Brush Machine Manufacturer Specializing in Tailored Solutions.

Brush Machine Manufacturer

In the modern manufacturing industry, efficiency, precision, and customization are critical factors in choosing the right machinery. As a leading Brush Machine Manufacturer Meixin Comb Brush Machinery specializes in delivering tailored solutions for businesses seeking high-quality brush production equipment. This article explores the essential aspects of brush machines, their applications, and why selecting the right manufacturer can significantly impact your production efficiency.

Understanding Brush Machines

Brush machines are specialized equipment designed to automate the production of brushes for various applications. From industrial cleaning brushes to personal care products, these machines ensure uniformity, precision, and high-speed production. As a brush machine manufacturer, our goal is to provide machines that are reliable, versatile, and easy to operate.

Types of Brush Machines

- Automatic Brush Machines

Automatic brush machines streamline production by reducing manual labor. They are ideal for large-scale manufacturing and can produce hundreds or thousands of brushes per day. - Semi-Automatic Brush Machines

These machines combine automation with manual operation, offering flexibility and cost efficiency for medium-scale manufacturers. - Specialized Brush Machines

Certain brushes require unique shapes, sizes, or materials. A reputable brush machine manufacturer can design and customize machines to meet these specific needs.

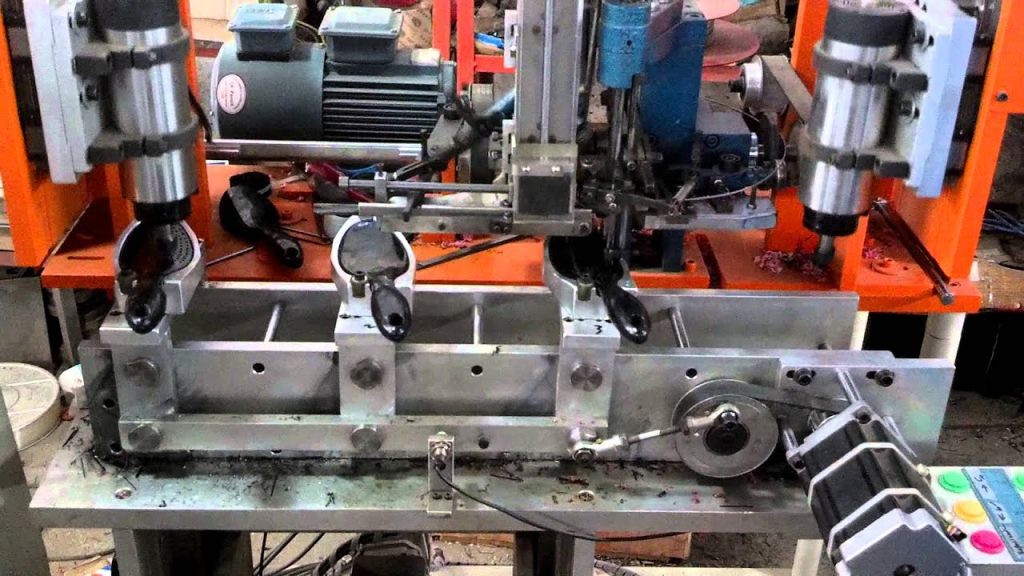

Components of a Brush Machine

A typical brush machine consists of several key components:

- Brush Head Assembly: Holds the bristles in place.

- Motor and Drive System: Powers the machine for consistent operation.

- Control Panel: Allows operators to adjust speed, density, and brush size.

- Feeding Mechanism: Ensures raw materials are delivered smoothly to the production line.

Applications of Brush Machines

Brush machines play a pivotal role in various industries. The versatility of these machines allows them to be used for:

Industrial Cleaning Brushes

Factories and workshops rely on heavy-duty brushes for cleaning machinery and surfaces. High-quality brushes manufactured using advanced machines ensure durability and effectiveness.

Personal Care Brushes

From hairbrushes to makeup brushes, precision is crucial in creating products that are both functional and aesthetically pleasing. A skilled brush machine manufacturer can provide solutions that maintain high standards of quality.

Automotive Brushes

Brushes used in the automotive industry require resilience and uniformity. Tailored brush machines help produce brushes that withstand high friction and wear.

Specialty Brushes

Specialty brushes for electronics, medical equipment, or food processing require precise bristle placement and consistent quality, which only a competent brush machine manufacturer can deliver.

Benefits of Choosing the Right Brush Machine Manufacturer

Selecting the right brush machine manufacturer can significantly impact production efficiency, product quality, and overall operational success.

Customization and Flexibility

Every business has unique production requirements. A reliable manufacturer offers tailored solutions, including customizable brush sizes, bristle types, and production speeds.

Enhanced Production Efficiency

High-quality machines reduce downtime and minimize material waste, leading to higher output and lower operational costs.

Technical Support and Maintenance

Professional brush machine manufacturers provide comprehensive technical support and maintenance services, ensuring smooth operation and longevity of the equipment.

Innovation and Advanced Technology

A manufacturer committed to innovation incorporates the latest technology in their machines, such as automated bristle insertion, smart control systems, and energy-efficient motors.

Key Considerations When Selecting a Brush Machine Manufacturer

Choosing the right manufacturer is crucial for ensuring the success of your brush production operations. Here are some essential factors to consider:

Experience and Reputation

A manufacturer with extensive experience has a proven track record of delivering reliable and high-performing machines. Client testimonials and case studies can provide valuable insights.

Customization Capabilities

The ability to provide tailored solutions is a hallmark of a professional brush machine manufacturer. This ensures that your specific production needs are met efficiently.

Quality Assurance

Machines should be built using high-quality components to guarantee durability, precision, and consistent output. A reputable manufacturer maintains strict quality control standards.

After-Sales Support

Reliable after-sales support is vital. A dependable brush machine manufacturer offers training, troubleshooting, spare parts, and maintenance services to maximize your investment.

Why Meixin Comb Brush Machinery Stands Out

As a leading brush machine manufacturer, Meixin Comb Brush Machinery specializes in delivering high-quality, customized brush production solutions. Our commitment to innovation, quality, and customer satisfaction sets us apart in the industry.

Tailored Solutions for Every Industry

We understand that different industries have unique requirements. From industrial cleaning to personal care, our machines are designed to meet diverse production needs.

Advanced Technology

Our machines incorporate state-of-the-art technology to ensure precision, efficiency, and ease of operation. Automated systems reduce labor costs while maintaining consistent product quality.

Dedicated Support

Meixin Comb Brush Machinery provides comprehensive technical support, including installation, training, and maintenance. We partner with our clients to ensure long-term success.

Commitment to Quality

We use high-quality materials and components to manufacture machines that are durable, reliable, and capable of high-volume production. This commitment ensures that our clients receive the best value for their investment.

Future Trends in Brush Machinery

The brush manufacturing industry continues to evolve, and staying ahead requires embracing new trends and innovations.

Automation and Smart Technology

Future brush machines will increasingly feature AI-driven automation, smart monitoring systems, and real-time production analytics. These technologies enhance efficiency and reduce waste.

Sustainable Manufacturing

Eco-friendly practices, such as energy-efficient motors and recyclable materials, are becoming essential in brush manufacturing. Leading brush machine manufacturers are integrating sustainability into their designs.

Customization and Niche Markets

Demand for specialized brushes is growing. Manufacturers who offer flexible, customizable machines will continue to lead the market.

Conclusion

Choosing the right brush machine manufacturer is critical for businesses seeking efficiency, precision, and quality in brush production. Meixin Comb Brush Machinery excels in delivering tailored solutions, advanced technology, and dedicated support to meet diverse industry needs. By investing in high-quality, customizable brush machines, companies can enhance production efficiency, maintain consistent quality, and stay ahead in a competitive market. For businesses looking to optimize their brush manufacturing process, partnering with a trusted brush machine manufacturer like Meixin Comb Brush Machinery is the key to long-term success.